IVAM - VALVES PETTENASCO - ITALY

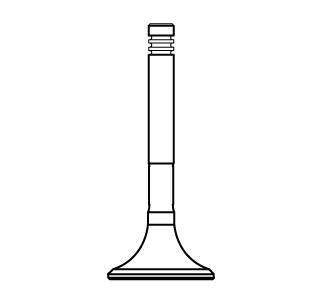

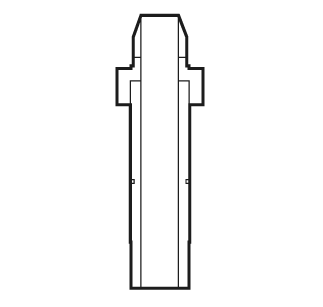

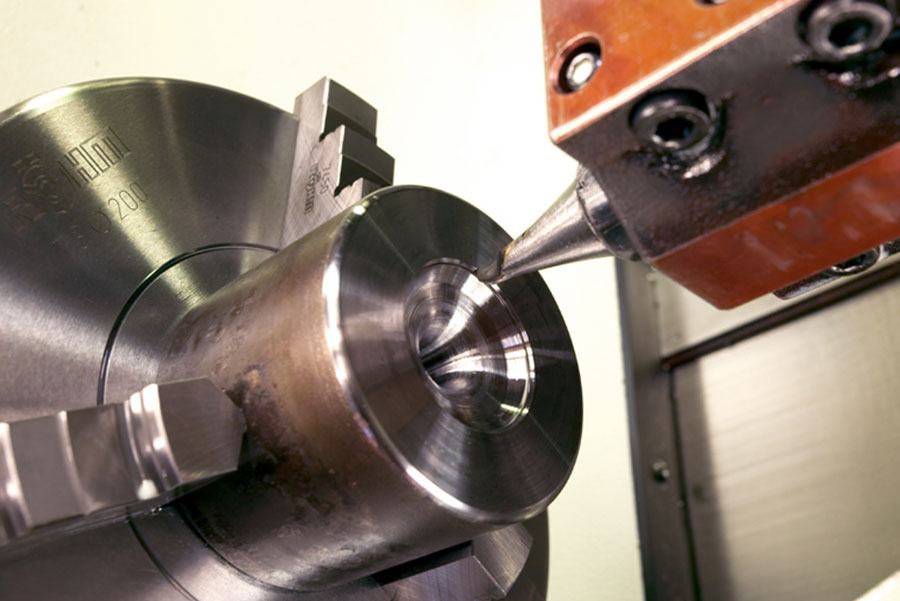

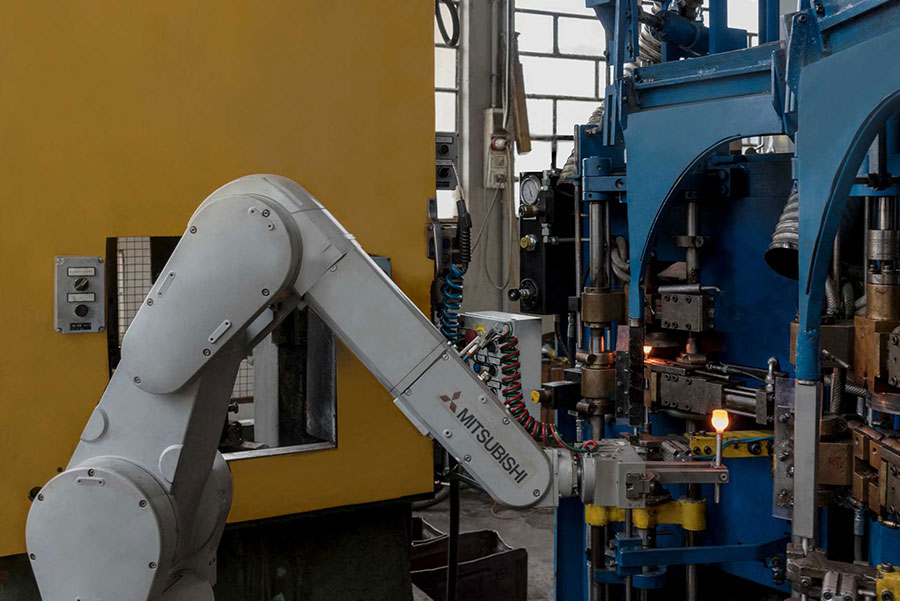

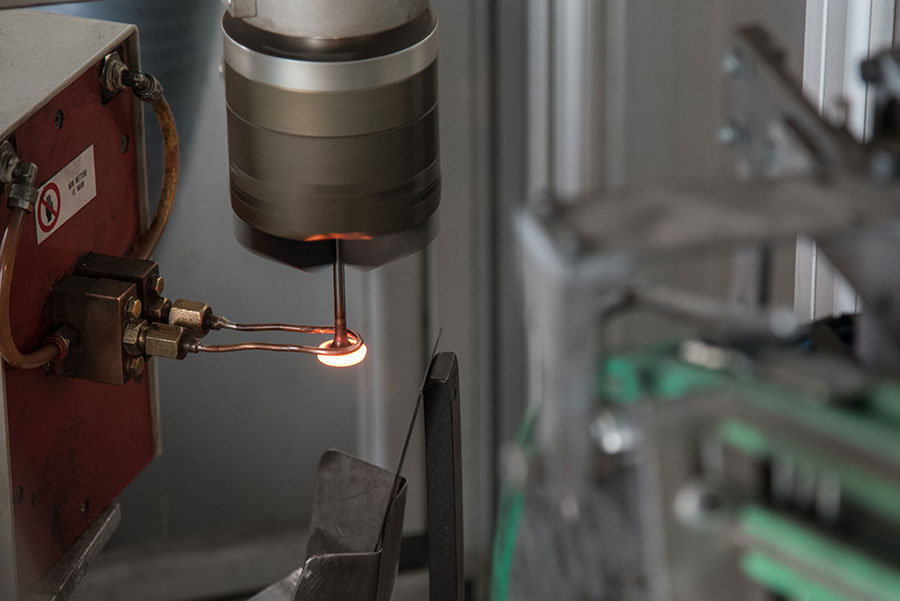

For more than 60 years , IVAM has been a leader in manufacturing quality Valves and Valve Guides in gas and diesel engines for cars, trucks, agricultural machinery, industrial engines, bio-gas generators, small/medium boat engines, earth movers, sport car racing and classic engine restoration.

On request, IVAM also makes Special Components to order, such as: special bolts, poppet valves for hydraulic and pneumatic systems and any other parts for all kinds of uses.

We also specialize in manufacturing Special valves for racing cars and classic engine restorations.

Contact us for more information about our valves or to request a quote

+39 0323 89136

ivam@ivam.it

Corso Roma, 81 28028 Pettenasco (NO) - Italia